Lifts for Wheel Alignment

One of the first features required in Wheel Alignment is positioning of the vehicle on a well levelled surface, that is each wheel must stay at the same level of the others.

For measuring the alignment,and possibly correcting it, it is necessary to execute some operations, at the vehicle side and also under it, so a lift is usually needed.

The lift is therefore the surface where the vehicle rests and it shall grant the necessary level for measuring, at any height the operator decides to work.

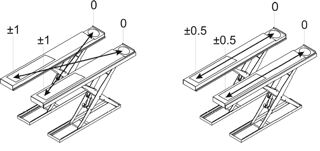

Some important car manufacturers require the following features for lifts intended for Wheel Alignment use:

- level between front and back side of the same runway, not lower than 0,5 mm;

- level between front side of one runway and back side of the other runway, not lower than 1 mm.

Starting from the requirements above, and also considering that the operator is given the possibility to choose the preferred working height, it becomes clear that the lift shall grant level surface with any kind of vehicle, up to the max. admitted weight and, according to what requested by EN 1493/98 Regulations, with reversible positioning of the vehicle.

What kind of lifts can meet the said requirements?

Before the "eve" of scissor lifts, there were 2 kinds of lifts used for wheel alignment operations: parallelogram lifts and 4-post lifts

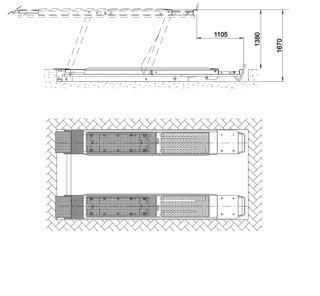

Parallelogram lift

Parallelogram lifts grant high performance in terms of level because, for their basic feature (that is parallelogram motion), the arm pivot pins don't change position according to the runway, at any height this might be.

Assuming that the runway structure has been so made to grant the requested rigidity (0,5 mm. max. flexion between front and back side, fully laden) levelling at 0,5 mm. from ground must be the same along the lift stroke.

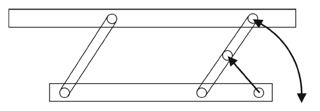

Diagram of movements of a parallelogram lift

Qualities: constant level at any working height; full embedding possibility; high reliability (no parts in motion, like wheels or slides); reduced service operations; easy installation; several adjusting positions, both at the front and at the rear plate supports (this is a typical feature of Giuliano lifts); suitable for wheel alignment accessories

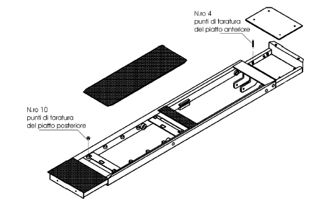

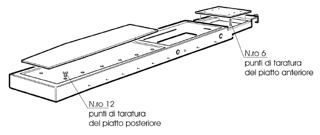

Diagrams of front and rear plate adjusting points of Giuliano parallelogram lifts

Drawbacks: reduced lifting height (1650mm. in embedded version); lifting movement combined with horizontal shifting so requiring a wider installation site.

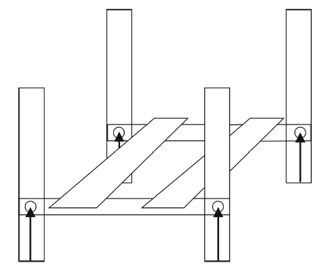

4-post lift

4-post lifts grant 4 resting fully rigid points outside the vehicle. The level quality is bound to the rigidity of the structure, that is to the flexion of the fully laden posts, the connecting beams, and the platform as well as to the quality of adjustment of the levelling system.

The higher is the height from ground (that is from post fixing point), the bigger is the criticality of the system.

Diagram of movements of a 4-post lift

Qualities: quite constant level (according to the rigidity of the product);vertical movement; low cost.

Drawbacks: considerable overall dimensions and high environmental impact; drive-on ramps required (embedding into ground is not possible) so increasing the overall dimensions, besides the vehicle size driven on it; installation operations and levelling adjustment operations are to be performed very carefully; not very suitable for wheel alignment accessories.

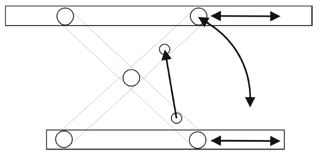

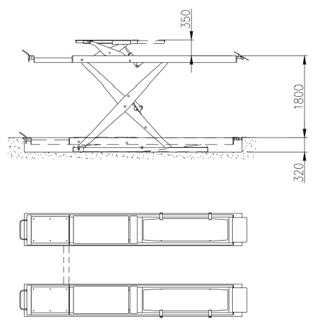

Scissors lift

The use of scissor lifts for wheel alignment operations had the aim of improving the working conditions of the operator thanks to a higher working

height and smaller overall dimensions.

The movement of scissor lifts is composed by a fixed fulcrum and by a sliding one, both on platform and on ground, where the lifting connecting rods (arms) are constrained. This feature (scissor) grants the platform vertical motion but, owing to the change of the resting point along the lift travel, the overhang side increases so bringing more weight and a bigger flexion to the whole structure; therefore the more the lift goes up and the bigger is the mobile platform flexion.

From what above it comes evident that the quality of scissor lifts in terms of levelling is granted by the rigidity of the structure in the even worst condition (that is fully lifted, fully laden and with load distribution according to the reversibility principles).

Diagram of movements of a scissors lift

Qualities: Lifting height, vertical movement, full embedding possibility, easy service, easy installation, several adjusting points both at the front and at the rear supports; suitable for Wheel Alignment accessories.

Recessing diagram and measures of a scissors lift

Diagrams of front and rear plate adjusting points of Giuliano scissors

Drawbacks: levelling bound to construction features and rigidity of the product.

If the scissor lift is not sufficiently rigid, level a-a1 changes according to rate d-d1

Conclusions:

All models described are available on the market, although covering different shares; final users choice is usually led by the use, more or less professional, of both lift and wheel alignment system.

All vehicles that are nowadays present on the market require more and more advanced lifts in terms of performances offered (wide range of applicable wheel base, steering rear axle, additional free wheel lift with same loading capacity as main lift).