At Giuliano Industrial we are proud of our products and their high quality. Technology behind the design of our New PAR-MOVE Concept Series arises from a fundamental requirement: each tire must always have one important feature - safety; that is why tire service professionals should use reliable high performance tire changers, able to professionally handle all kinds of tire assemblies, even the most challenging ones, without any risk of damaging rim or tire, so granting the highest possible drivers' safety.

Many factors may significantly affect tire safety while mounting/demounting. For instance, excessive plays on tire changer structure may generate further issues not only on tire but even on wheel.

Our new PAR-MOVE Concept Series grants much higher rigidity than any conventional tilt back model. There are many reasons why you should consider buying PAR-MOVE Concept machines, and here we would like to highlight the most important technical information about it.

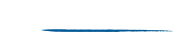

PAR-MOVE Concept Series vs traditional tire changers

A) Mechanical plays due to stress have been drastically reduced:

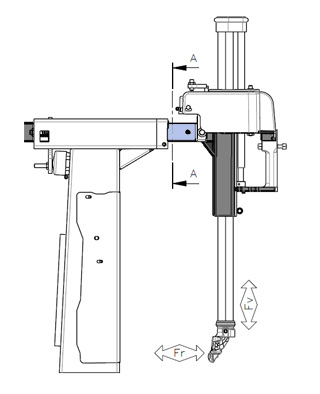

- Articulated parallelogram movement of the operating arm uses pivot points and bushings with minimum tolerances. The New PAR-MOVE system has been designed to enable the operator in the assembly line to perform the adjustments in order to eliminate all plays and flexes by simply tightening the nuts which secure the through-pins.

- The movement of the traditional horizontal arm is carried out through sliding parts, provided with less precise treatments such as broaching, which cannot provide the same system precision as the pins and bushings used on the PAR-MOVE system. The reduction of mechanical plays depends on the skills and experience of the operator in the assembly line, who manually carries out all adjustment by acting on rollers and cut bushings in order to reduce mechanical plays and flexes.

|

|

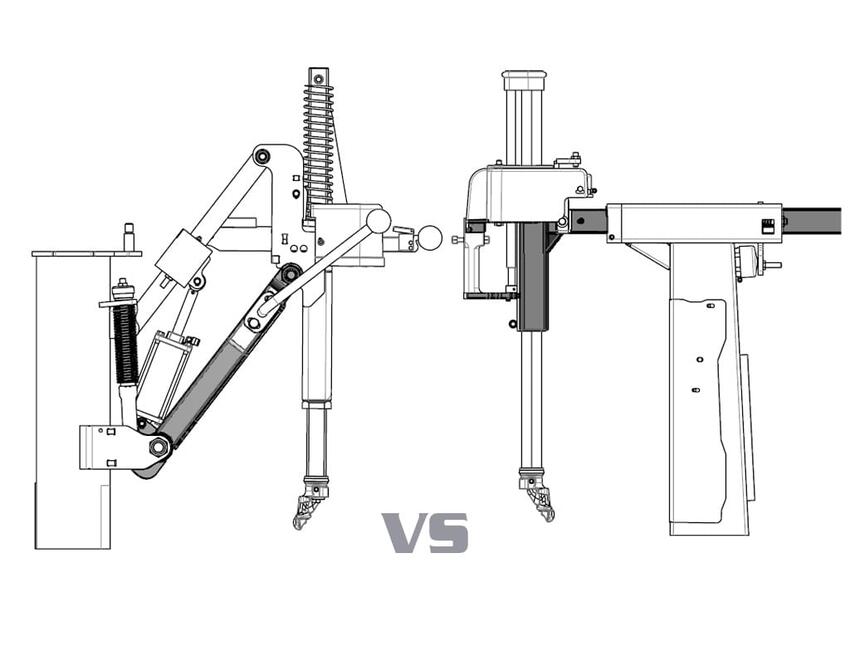

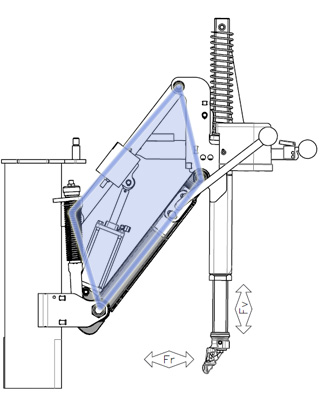

B) Resistance Under Stress:

- The new design of parallelogram arm, a truly unique technology on the international market, moves as a perfectly symmetrical parallelogram, allowing a greater resistance against flex due to stress caused by the mechanical forces during the mounting/demounting operations, and significantly reducing all visible and non-visible flex on the demounting tool.

- in the traditional horizontal arm all forces are applied in the front area of the vertical tower head.

|

|

C) SPACE SAVING Machines:

- The new vertical tower is not tilting. Thanks to articulated parallelogram movement of the operating arm, the new Giuliano machines do not require any additional rear and side space, as with conventional tilt back models, and can be installed in a working space perfectly fitting its actual overall dimensions.

- Traditional tilt back tire-changer must be positioned at least 1 m away from the wall, and swing arm tire changers with lateral movement not only need extra space, but just allow the installation of auxiliary helper arms on one side of the tyre changer, only; which makes them difficult to use.

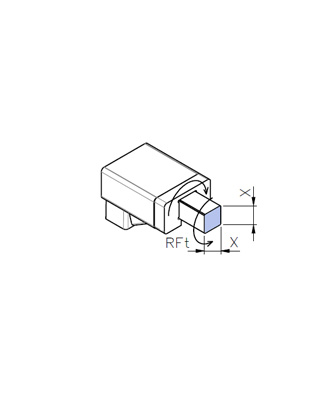

Thanks to Spiderfrog, an innovative measuring device especially designed by GIULIANO GROUP and certified in Germany by Staatliche Materialprüfungsanstalt (MPA), Darmstadt, company credited by DaKKs, we will test all tire changers to show how robust, stiff and rigid our tire changers are under stress while performing their everyday working tasks.