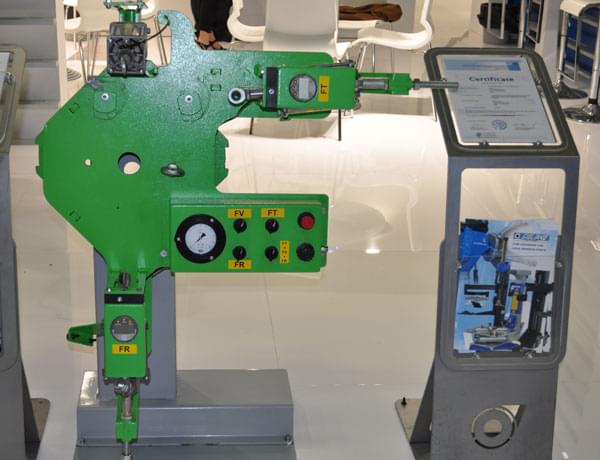

Spiderfrog® is an innovative measuring device, certified in Germany by Staatliche Materialprüfungsanstalt (MPA), Darmstadt, company credited by DaKKs.

Spiderfrog® has been especially designed by Giuliano Industrial S.p.A. in order to check and measure bending and torsion of tire changers' main parts under stress, which typically occurs during tire mounting/demounting operations.

After 3 months of testing, MPA has confirmed the reliability of measurements carried out by Spiderfrog®, thus certifying it as a really effective and useful device.

How does it work?

Stress is determined on tire changers by a combination of forces, which are normally activated during tire rotation, when tire changer's operating arm is engaged in mounting and/or demounting the tire bead on/off the rim.

Through Spiderfrog® device, Giuliano Industrial has found an interesting way to measure these forces, combine them in a calculated “Combination Force”, and find a “Resistance Under Stress Coefficient” (RUSC), which gives some idea of how robust/strong a tire changer can be, in terms of strength and power against all different kinds of stress involved in mounting/demounting tires.

Spiderfrog® is clamped on a traditional turntable, simulating the size of a 16” rim, and its structure includes electronic measuring systems connected to air operated cylinders, to simulate the main forces (and related stresses) involved in tire mounting/demounting operations. Every electronic gauge measures the movement, which is given by each single force applied to the tire changer. Air cylinders have been sized in a proper way to simulate the highest possible power applied on each part of the tire changer, during mounting/demounting operations.

For further information on Spiderfrog®, please click here.

Why use Spiderfrog® ?

Flexes during tire mounting/demounting operations are necessary to protect the tire (the most delicate and important element of the tire assembly) against permanent damages, which may even compromise vehicle safety.

Excessive flexes, though, may generate further issues, which in turn are likely to create problems not only to the tire but even to the wheel. Therefore, Giuliano decided to conceive and develop Spiderfrog® with the aim of offering its customers high performance equipment complying with specific preset flexure requirements.

At design/development stage of each new model, Spiderfrog® allows to verify. Much more than any other virtual simulator, if the machine structure corresponds to the initial project requirements.

At production stage, Spiderfrog® can be profitably used in assembly lines by Quality Control Department to test and reject any machines, which do not strictly comply with the required tolerance values.

When purchasing a tire changer, Spiderfrog® can also be used to compare two different tire changers by mounting it either on Giuliano’s or competitor’s tire changer, so as to enable customer to evaluate product quality and to find the strongest tire changer.